Detection Technology

DETECTION TECHNOLOGY

Detection principle

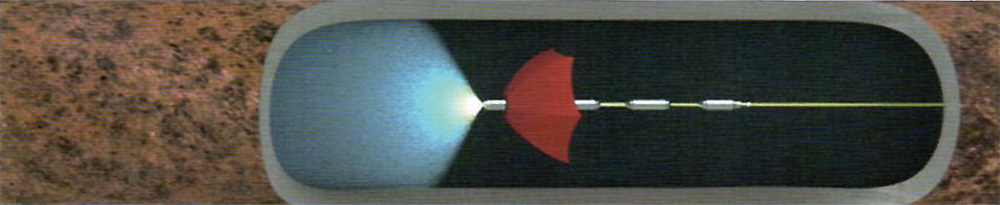

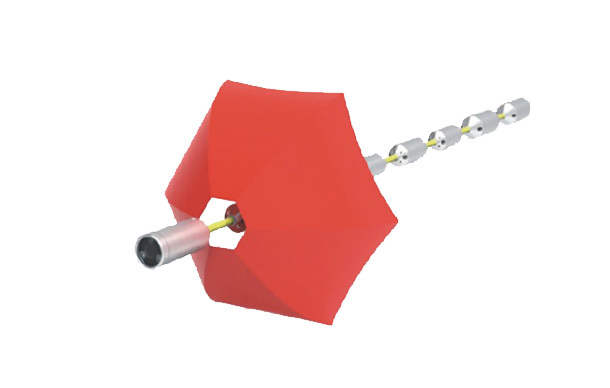

The detector in the water supply pipeline is a powerful helper for the investigation and detection of the water pipeline. Using high-sensitivity hydrophone and high-definition camera unit, it can effectively detect various abnormal situations such as small leakage, damage, tube tumor, bubble, impurity deposition, etc., and transmit the detection situation back to the ground control unit in real time through the photoelectric composite cable connected to the tail. At the same time, with the help of the ground beacon system, accurate positioning of abnormal situations can be realized. Some pipelines are missing routing information due to their age, and this product can also be applied to achieve routing reconfiguration.

Common Testing Equipment

Size: outer diameter 350mm

Applicable pipe diameter: ≥ 1000mm

Design detection distance: 6km

Size: outer diameter 80mm

Applicable pipe diameter: ≥ 400mm

Design detection distance: 6km

Size: outer diameter 60mm

Applicable pipe diameter: ≥ 400mm

Design detection distance: 2km

Application Effect

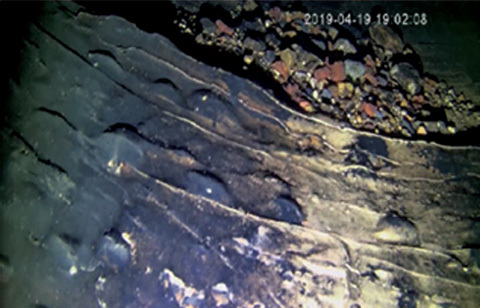

Stacking stones at socket position

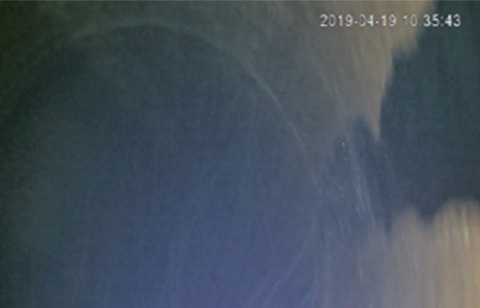

Air bag

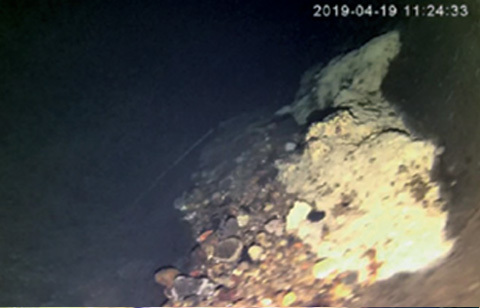

Socket sealing ring falling off

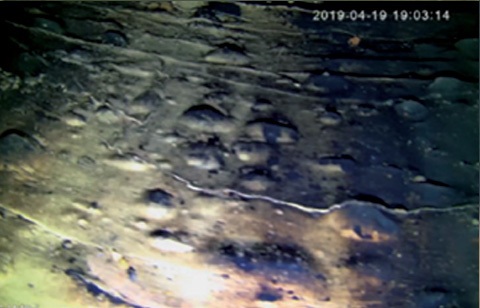

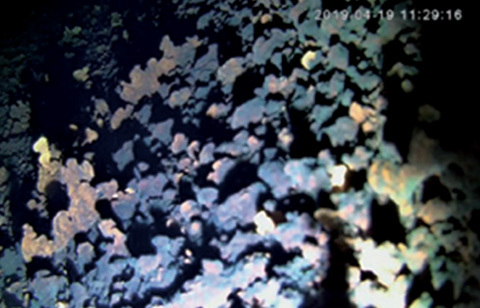

Tube internal tube tumor

Relatively serious accumulation of stones

Water pipe inner wall

Equipment Features

● Adopt high-sensitivity audio acquisition system, real-time acoustic signal return

● Equipped with high-definition camera, full visualization, to ensure high detection accuracy

●It can detect small leakage of pipeline, inner wall defects of pipeline, pipeline routing, air bag in pipeline, etc.

● Accurate positioning of abnormal points/leakage points, and repeated inspection of suspicious locations

● No need to shut down the pipeline to minimize the impact on water supply

● Efficient noise reduction algorithm to effectively suppress interference signals

Technical Indicators

Suitable for all kinds of pipes: steel pipe, cement pipe, PVC, PE, etc

● Applicable pipe diameter: DN400 ~ DN4000

● Applicable pipe pressure range: 0.1MPa ~ 1.0MPa

● Pipeline medium flow rate requirements: 0.2 m/s ~ 1.0 m/s

● Opening diameter: ≥ 150mm

● Clearance requirements for receiving and sending positions: ≥ 2m

● Detection distance: standard condition 2Km, limit 6Km

Other Testing Equipment

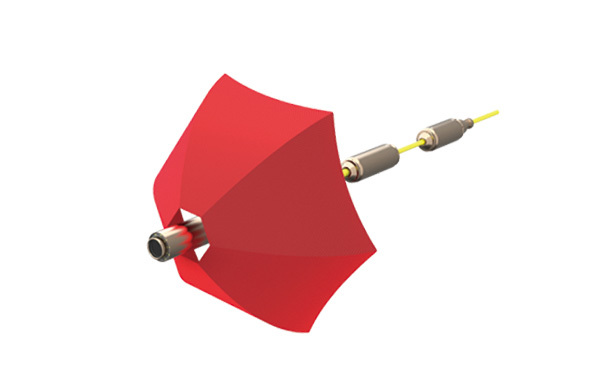

PCCP broken wire electromagnetic detector

PCCP broken wire electromagnetic detector can work in the pipeline water stop state, by detecting the change of excitation magnetic field caused by broken wire, identify the distribution of broken wire of PCCP pipeline, so as to evaluate the safety of the pipeline.

·Efficient and reliable

· Detectable pipe diameter: 1.4m ~ 4.0m

· Detectable minimum number of broken wires: 1~5

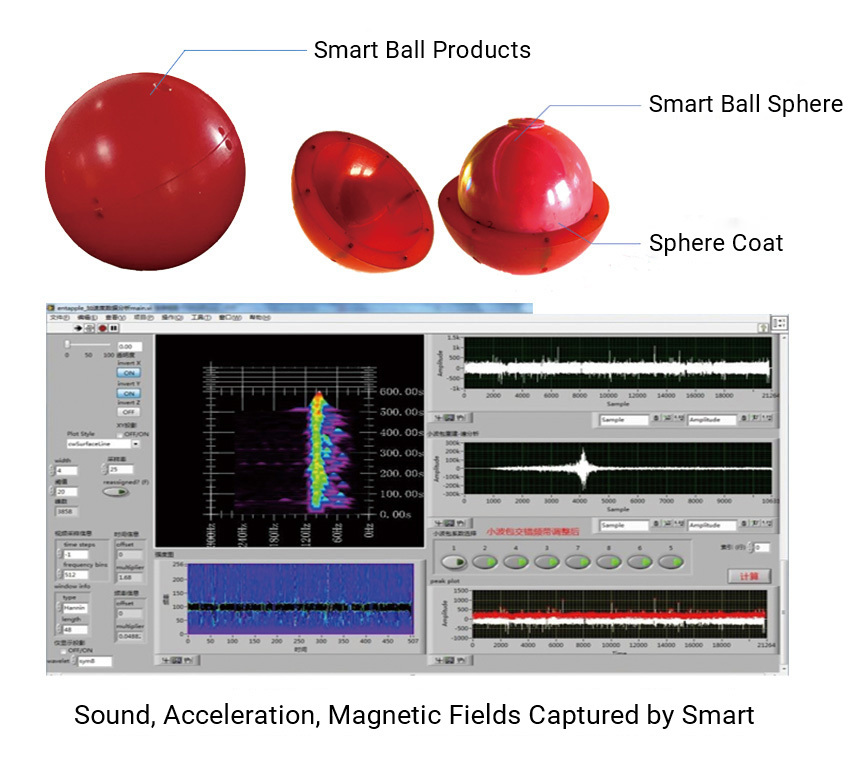

pipe spherical inner detector

The pipe spherical inner detector can detect and accurately locate the small leakage of the pipe. After the detector is put into the pipeline, it can roll along the pipeline with the flow of liquid. The sensor mounted inside it can collect the sound, acceleration, magnetic signal and other information along the pipeline, and effectively capture the pipeline leakage signal when the sphere passes through the leakage point. After the detector is recovered, relevant information such as pipeline leakage and pipeline direction can be extracted through the data analysis system, and the location of the leakage can be accurately located and the leakage magnitude can be estimated.