TECHNICAL SERVICE

Technical Services

Repair Technology

REPAIR TECHNOLOGY

In-situ Thermoplastic Forming Pipe Repair

Referred to as FIPP(formed-in-place pipe). The prefabricated I-shaped or C- shaped cross-section lining pipe is heated and softened at the construction site, pulled into the inside of the original pipeline, and then cooled to form a lining pipe with structural strength to realize the repair of the aging pipeline.

Hose interpenetration lining technology

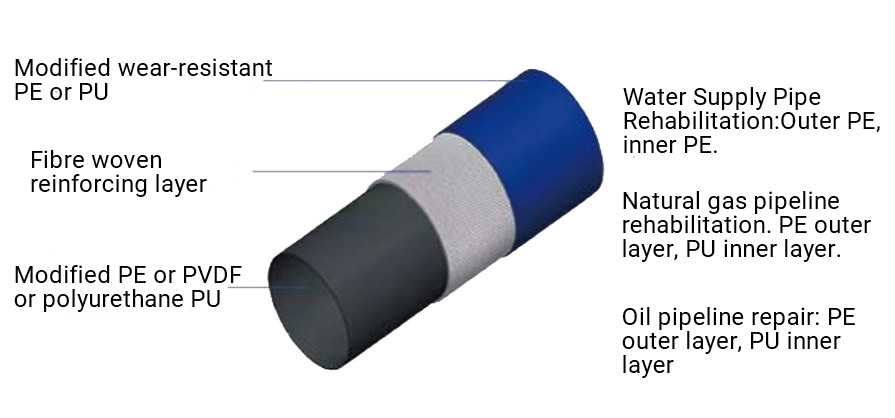

The circular fiber reinforced plastic hose is placed in the pressure pipe to form a permanent pipe structure or a circular lining under the action of fluid pressure, which has the advantages of high pressure resistance and long single repair distance.

CIPP in-situ curing method

Cured-in-place pipe (Cured-in-place Pipe) refers to the repair method of putting the resin-impregnated hose into the original pipe by turning or pulling, and forming the pipe lining after curing. The curing process of the hose currently includes: hot water curing method, steam curing method and ultraviolet curing method.

Cement-based slurry spraying method

The repair method of evenly covering the cement-based material for repair on the inner surface of the pipeline facility to be repaired by centrifugal or pressure jet to form a lining. This method is applicable to the repair of inspection wells, pipes of various diameters and box culverts, and can be used for structural repair as well as functional repair.

Sincerely look forward to working with you to create a better tomorrow

Committed to providing pipeline manufacturing and technical solutions for global users

Contact Immediately →Contact Information

Office telephone:

0086-533-4291123 / Shandong Zibo

0086-519-68196652 / Changzhou, Jiangsu

Registered Address: No. 36 Jianshan East Road, Boshan District, Zibo City, Shandong Province

Headquarters address: 533 Yanjiang East Road, Xinbei District, Changzhou City, Jiangsu Province

Copyright©2023 All Rights Reserved of Shandong Longquan Pipe Industry Co., Ltd.